Engineering Resilience: What Makes Modern Components Reliable

Consumer products, industrial machines, vehicles, infrastructure, and buildings must perform predictably despite stresses, shocks, weather and wear from use. Companies recognize reliability drives customer satisfaction, safety and profits. While robustness originates from sound designs, translating resilient plans into durable finished goods involves material science, precision manufacturing, and advanced quality testing to confirm designs meet demands.

Modeling Stress Dynamics

Engineering resilient systems starts with computer aided design (CAD) modeling to preview product performance in silico. Sophisticated finite element analysis software simulates stress flows digitally across components, revealing failure risks when specific forces get applied whether rotational, compressive, shearing or torsional. Design teams validate 3D models experimentally using 3D printers to compare test data with simulation predictions fine tuning designs where analytical assumptions are misaligned from physical sample behaviors.

Material Science Matters

Material choice heavily influences device lifecycles from sporting gear to satellites. Metallurgists formulate alloys balanced across strength, fracture toughness, corrosion resistance, thermals, magnetic response, weight and other attributes a given application prioritizes because no single metal optimizes all properties. Where metal falters, polymers, composites and ceramics enter, such as insulating wounded rotor efficiencies. Pairing optimal materials to design geometries makes it possible to endure punishing real-world conditions.

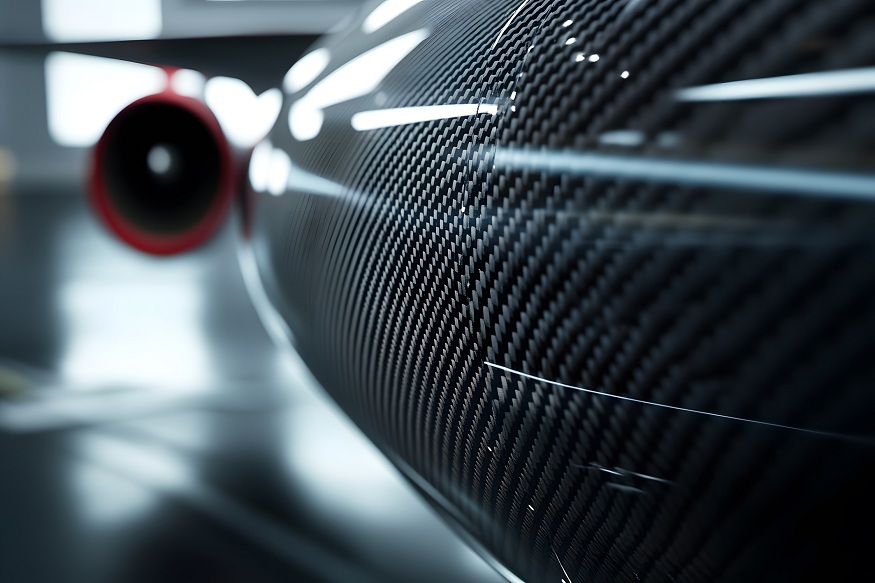

Precision Manufacturing Processes

Fabricating resilient engineering designs requires tightly controlled methods, generating minimal flaws that sabotage longevity. Casting, machining, molding, and additive techniques demand procedural rigor, keeping impurities and porous defects to near zero through regulated temperatures, programmed sequences and clean room environments. For example, void free composites cure inside autoclaves under vacuum pressure before CNC trimming. Likewise, additive manufacturing utilizes high purity alloy powders and exacting lasers producing intricacies impossible otherwise.

Critical Component Redundancy

Mission critical systems use component redundancy to hedge against possible points of failure. Airliner hydraulics operate multiple independent lines so if one gets damaged, the others preserve function, avoiding catastrophe. Server farms similarly run parallel computers should units crash. The approach applies to small scales too, with consumer devices carrying extra batteries, cameras with dual SD slots and heavy trucks outfitting extra alternators. Doubling up components critical to overall reliability reduces risk exposure to random part wearing out or breaking.

Smart Structural Health Monitoring

Networked sensors monitor key parameters in real-time across complex assets, spotting emerging issues early. Bridges have arrays of smart sensors tracking vibrations, tilts and cracks in concrete, sending alerts over slight changes indicating repairs needed optimizing maintenance timing before critical failures. Airplane black boxes serve this purpose, logging hundreds of data streams for crash investigation, and mass spectrometers sniff factory air identifying oil vapors hinting worn bearings prior to full failure. Health monitoring insight improves preventative reliability.

Epoxy Film Adhesive Bonding

Many devices secure parts together using mechanical fasteners or welds. But environmental factors conspire to loosen joints. According to the folk over at Axiom Materials, advanced epoxy film adhesives create strong, lightweight bonds between metals and composites, surpassing traditional methods by maximizing surface contact and eliminating the need for fasteners. The film adhesive cured connections resist corrosion, shocks and micro-cracks that defeat older methods.

Quality Control Framework

Variation threatens reliability. Standardized controls (viscosity, torque, laser measurement, extrusion monitoring) ensure consistent, high-quality production. Sharp quality frameworks spot inconsistencies fast to prevent potential weaknesses entering supply chains.

Conclusion

Creating reliable, long-lasting products in the face of stress involves coordinating resilient engineering concepts, finite element stress modeling, robust materials, precision manufacturing controls, redundant subsystems and stringent quality frameworks confirming designs meet demands during real world operation. When executed properly from conception through production, modern components withstand challenging environments and changing conditions, keeping people safe while enabling advancement. Reliability proves essential across all technology.

Post Comment

You must be logged in to post a comment.